| Sign In | Join Free | My udpf.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My udpf.com |

|

Brand Name : Jufu

Model Number : JFRO-1T

Certification : ISO9001/CE

Place of Origin : China

MOQ : 1 unit

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Delivery Time : 2-4 weeks

Packaging Details : Export standard wooden box (like plywood), no need to fumigate, really suitable for shipping.

Type : Reverse Osmosis

Capacity : 1000L/H

Warranty : 12 Months

After-sales service provided : Online support

Product name : RO water treatment system

Function : Wate Purification

Voltage : 110V/220V/380V can be customized

Membrane Size : 4040

1000LPH FRP Water Purification Ro Water Treatment Plant Double Stage

Reverse osmosis water treatment system has poor filtration effect:

There are many reasons for the poor filtering effect, such as: the selection of filter material variety, filling amount is unreasonable, filter cycle backwash scrubbing time control is unreasonable, will lead to high SDI.

Low removal rate of organic matter

1. Improve the pretreatment process and improve the measures of COD reduction in the system

2. Try to replace other non-oxidizing fungicides for COD removal.

3. Replace or regenerate when the COD adsorption of the filter material of activated carbon filter is full.

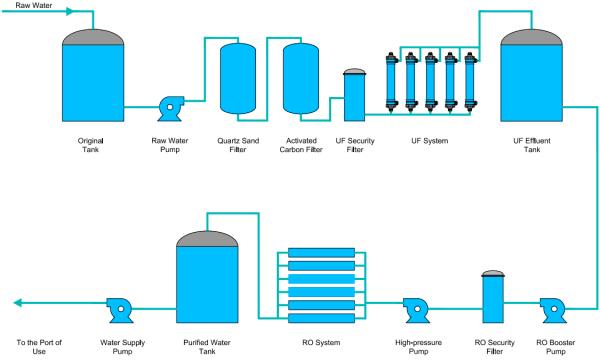

Reverse osmosis technology process

RO membrane itself is sensitive to the pH, temperature and specific chemicals of the influent. The water quality of the influent strictly requires the pH value range of 4~10, temperature <40℃, silt density index SDI<5, free chlorine <0.1mg·L-1, turbidity <1, iron content <0.1mg·L-1, etc. In order to meet the requirements of RO membrane water, raw water before entering the RO membrane system must first preprocessing (sedimentation, coagulation and microfiltration, ultrafiltration, activated carbon absorption, pH adjustment, etc.), then the pump pressure into the membrane module, the pressure under the action of raw water as water production through the RO membrane, and inorganic salts, organic matter and particle by RO membrane intercept on the other side of the membrane to form thick liquid. The concentrated solution can be recycled or reprocessed according to the requirements of the specific process. RO can be used with ultrafiltration, nanofiltration and other membrane devices to form an integrated membrane device.

Working Principle of Reverse Osmosis Water Treatment System:

When a pressure greater than osmotic pressure is applied on the saltwater side of the membrane, the flow of water is reversed and the water in the saltwater flows into the fresh side, a phenomenon called reverse osmosis.

Technical Specifications of Reverse Osmosis Water Treatment System:

| 1m³/h Reverse Osmosis System | |

| Model | JFRO-1000L |

| Host Size | 1000x600x1600mm (can be customized) |

| Power | 2.2KW |

| Power Supply | 220V /380V/460V - 50Hz/60Hz,220V 50Hz can be customized |

| Operating Pressure | 0.8-1.2MPa |

| Recovery Rate | 50% |

| Designed Water Inlet | 2000L/h |

| Outlet Flow | 1000L/h |

| Desalination Rate | ≥99.5% |

| RO Frame | SUS304 |

| Membrane Size | 4040 |

| Membrane Elements | DOW /Hydranautics/Troy/ Vontron (Optional) |

| Number of Membranes | 4 |

| Raw Water Pump | CNP/NYP/GRUNDFOS (Optional) |

| High Pressure Pump | CNP/NYP/GRUNDFOS (Optional) |

| Tank Material | SS/FRP(Optional) |

| Control Valve | Manual/Automatic |

| Control Valve Brand | FLECK/RUNXIN |

| Membrane Housing | SS/FRP |

| Pipe Material | U-PVC/ Stainless steel (Optional) |

Process flow of reverse osmosis water treatment system:

Raw water → original water tank → original water pump → multi-media filter (quartz sand filter)→ activated carbon filter → soft water processor → precision filter → high pressure pump → first stage reverse osmosis (RO) device → pure water tank → high pressure pump → second stage reverse osmosis → ultraviolet sterilization device → water point

Manufacturing, installation and commissioning of reverse osmosis water treatment equipment:

Users should monitor the whole process quality and process of manufacturing process equipment according to the design requirements, and grasp the quality assurance of selected materials and components.

In the process of equipment installation, the installation position and physical and chemical indexes of instruments and filling materials (filter media, resin, hollow balls, etc.) are strictly located and inspected.

In the debugging process, the additives and consumables used in the operation process should be tested qualitatively and quantitatively. Special attention should be paid to the compatibility of PAC, PAM, scale inhibitor, etc., and the suitable operating consumables for the system should be selected through tests.

![]()

FAQ:

1, What are the inlet water quality requirements for ro water treatment system membrane components?

| | NTU | SDI | Residual chlorine(mg/L) | Fe2+(mg/L) | TOC(mg/L) |

| Limits | ≤1 | ≤5 | ≤4 | ≤3 |

2. What is the material of ro water treatment system membrane?

Acetate membrane (CA) : mainly because of its resistance to chlorine, so it is still durable. But its suitable pH range is small, easy hydrolysis

Aromatic polyamide membrane (PA) : water almost can not have chlorine, only through a variety of pretreatment chlorine.

3. RO water treatment system configuration:

First-stage multi-stage process: if the recovery rate is not achieved in the first stage (50-65% in the first stage and 65-75% in the second stage), the multi-stage tandem filtration can be used. The effective cross-sectional area of each segment decreases. 2:2 and 2:3 and 4:2:1

Multi-stage process: when the first stage process cannot meet the effluent quality requirements (the first stage is generally ≤20μs/cm), the product water of the first stage process is sent to another reverse osmosis unit.

The arrangement of membrane components can be divided into series and parallel.

|

|

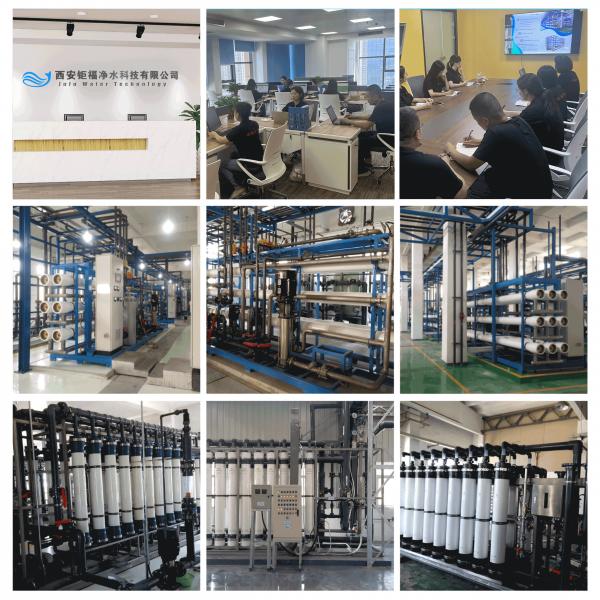

1000LPH FRP Reverse Osmosis Water Purification Plant Double Stage Images |